Volvo Trucks are generally regarded as highly reliable and robust. Over the years, this has made them a firm favourite with UK hauliers. As with any commercial vehicle with a heavy workload, Volvo Trucks can be susceptible to a range of problems over time. Most of these are fairly minor and can be rectified easily, particularly if they are identified at an early stage. Volvo Truck air suspension problems, Volvo Truck air dryer problems, and Volvo Truck air compressor problems can all occur. What potential issues with these systems do drivers, hauliers and fleet managers need to be aware of?

Volvo Truck Air Suspension Problems:

Leaking Airbags

Over time, the rubber components of airbags may deteriorate, leading to air leaks. This can result in reduced handling and uneven ride heights. It can also increase the wear on other suspension components.

Faulty Height Control Valves

Height control valves regulate the air pressure in the suspension system maintaining the correct ride height. The valves can become clogged with debris and will sometimes malfunction. When this happens, it can lead to issues such as uneven suspension, excessive bouncing, or difficulty maintaining the correct alignment.

Air Line Leaks

Wear, corrosion, and damage can all lead to issues developing on air lines and fittings in the suspension system of Volvo Trucks. When this happens, it can cause a loss of air pressure, affecting the stability and handling of the truck. Regular inspections and timely maintenance are essential for addressing air line leaks.

Volvo Truck Air Dryer Problems:

Moisture Build-Up

If the air dryer in a Volvo Truck’s air brake system fails or becomes ineffective moisture can accumulate in the system. This can lead to reduced braking efficiency and potential damage to brake components.

Clogged Desiccant Cartridges

The desiccant cartridges inside the air dryer are responsible for absorbing moisture from the compressed air. Over time, these can become saturated with moisture and debris which reduces their effectiveness. Regular maintenance, including replacing desiccant cartridges, is essential to prevent the problem.

Volvo Truck Air Compressor Problems:

Low Air Pressure

When an air compressor malfunctions it can result in insufficient air pressure in the truck’s air brake system. This can result in brake performance issues, including extended stopping distances and potential brake failure. Regular maintenance of the air compressors will include ensuring proper air pressure levels.

Excessive Noise or Vibration

Internal mechanical problems such as worn bearings or damaged pistons in the air compressors may result in unusual noise or vibrations. Addressing these issues promptly can prevent further damage to the compressor.

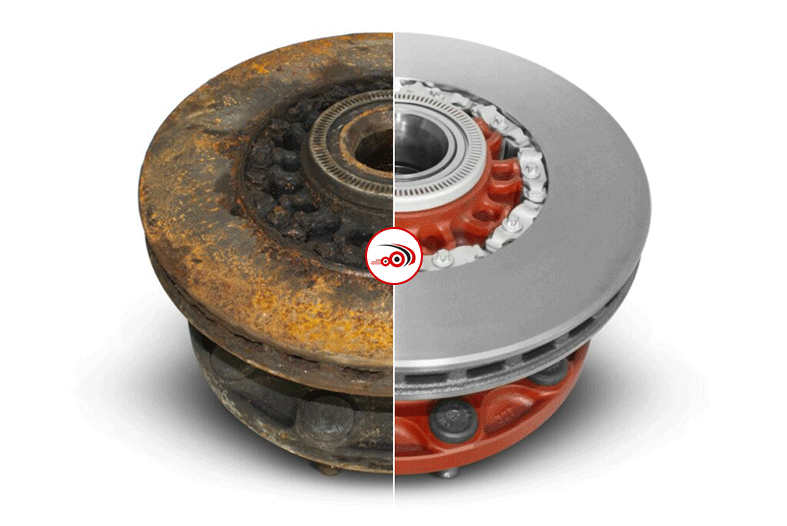

Volvo Truck components from CV Hubs & Bearings

At CV Hubs & Bearings, we’re specialists in all things HGV wheel hubs. Our experienced team is always on hand to answer any questions you may have. We stock an extensive range of Volvo Truck wheel hub components to ensure your Volvo trucks can stay on the road for longer.

Contact us to find out more about our services

Back to news