If you’re operating any kind of haulage business or service, maintenance and repair tasks are crucial. They ensure the safety of your fleet, drivers, and other road users, as well as optimal performance. There are a variety of tools used in the maintenance and servicing of HGVs and one of these is the wheel hub puller.

What is a wheel hub puller?

A wheel hub puller is a frequently used tool developed for HGV maintenance. It has been designed to facilitate the safe and efficient removal of the wheel hub from the vehicle. It’s used when the hub assembly has been tightly fitted and requires additional force to separate it from the vehicle’s axle or wheel hub.

A wheel hub puller will typically be made up of a central bolt or nuts, a body or frame, and jaws or hooks that grip onto the hub assembly. The puller applies force to the hub assembly, and this gradually separates it from the axle or wheel hub.

There are different types of wheel hub pullers available. These include the three-jaw and four-jaw designs, such as hydraulic pullers. Each design has a range of advantages, making them suitable for different types of vehicles or particular maintenance tasks.

HGV wheel hub pullers are designed to withstand the heavy-duty nature of HGV vehicles and the higher torque requirements involved in removing their hub assemblies.

This enables mechanics to easily perform necessary repairs and maintenance by safely removing the wheel hub when necessary.

What are wheel hub pullers used for?

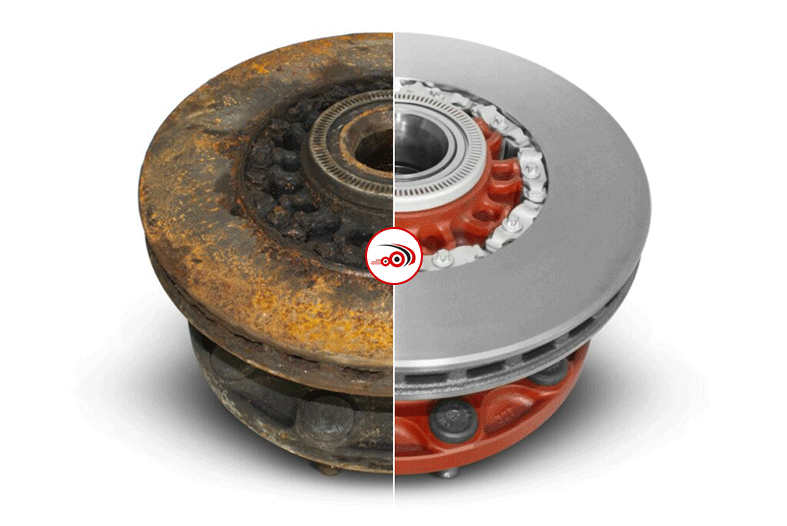

As mentioned above, wheel hub pullers are designed to remove the wheel hub from the vehicle in a safe and efficient way without causing damage to the surrounding components or the vehicle itself. Factors such as wear and tear or rust can make it more challenging to remove the hub assembly. When this happens, the mechanic may use a wheel hub puller.

The wheel hub puller gives the mechanic the ability to overcome the resistance and dislodge the hub assembly from its position.

Wheel hub pullers are commonly used when replacing wheel bearings. These are the essential components that allow the wheels to rotate smoothly. Over time, these bearings can wear out and will require replacement. When this happens, a wheel hub puller will then be used to remove the hub assembly, allowing for the replacement of the wheel bearings.

As well as replacing wheel bearings, wheel hub pullers are used for various HGV maintenance tasks. They assist in brake system maintenance by separating the wheel hub assembly from the vehicle, allowing mechanics to replace components such as discs or rotors.

Wheel hub pullers might also be used during suspension repairs, allowing the mechanic to access and replace key suspension components. They’re also used to aid wheel stud replacement, as well as axle maintenance and repairs. Finally, when replacing brake rotors or drums, the wheel hub puller is used to remove the hub assembly, allowing for the replacement of these parts.

What are the advantages and disadvantages of a wheel hub puller?

Wheel hub pullers offer efficient and time-saving solutions for removing wheel hub assemblies. They provide a secure grip on the hub assembly, enabling controlled and evenly distributed force application, which reduces the time and effort required compared to alternative methods.

Wheel hub pullers also minimise the risk of damage to the hub assembly and surrounding components. They safely detach the assembly without causing harm to other parts, ensuring the preservation of the components involved.

Wheel hub pullers are available in various sizes and configurations, and this means they can accommodate different types of vehicles and hub assemblies. This versatility allows mechanics to find the right tool for their specific needs, making it easier to work on a wide range of vehicles.

Crucially, wheel hub pullers make wheel hub removal significantly safer. They apply force in a controlled manner, reducing the risk of accidents or injuries caused by sudden movements or slips. The wheel hub puller grips the hub assembly securely, making the removal process more stable and controlled. This reduces some of the potential hazards associated with hub assembly removal.

Wheel hub pullers are a significant investment, particularly for higher quality models. If you only work on wheel hub assemblies infrequently, then this may mean they’re not cost-effective.

Using a wheel hub puller effectively and safely requires a certain level of expertise to ensure safe and effective use. Improper use can result in damage to the hub assembly or other components. It’s also important to remember that wheel hub pullers are designed for a specific purpose and inappropriate use is likely to be counterproductive.

How do you use a wheel hub puller?

If you intend to use a wheel hub puller it’s important to take a systematic approach to ensure that it’s used correctly. This needs to consider safety, as well as the appropriate use of the wheel hub puller to ensure that parts are not inadvertently damaged through its use.

There are a number of steps to follow in order to safely use a wheel hub puller. These are:

Step 1: Preparing for the Task

Before starting, gather the necessary tools and equipment, including the wheel hub puller specifically designed for the type of vehicle you are working on. It’s essential that you wear the appropriate personal protective equipment (PPE) before beginning the task. Typically, this will include safety glasses and gloves.

Step 2: Ensure the Vehicle is Safely Parked

Safely parking the vehicle is crucial when using a wheel hub puller. Begin by choosing a level surface and engaging the parking brake fully. Use wheel chocks or blocks to prevent the vehicle from rolling. Lift the vehicle using a hydraulic or floor jack, and then support it with sturdy jack stands. Make sure you secure any loose items in or on the vehicle, maintain a clean work area, and prioritise safety throughout the process.

Step 3: Remove the Wheel

It’s now time to remove the wheel. Using a lug wrench or a socket, loosen the lug nuts of the wheel that corresponds to the hub assembly you want to remove. After you have removed the lug nuts you can then take off the wheel, exposing the hub assembly.

Step 4: Positioning the Wheel Hub Puller

Identify the appropriate attachment points on the wheel hub puller that will securely grip the hub assembly. The puller may have hooks, jaws, or bolts that fit onto the hub assembly. Ensure that the puller’s design matches the configuration of the hub assembly and always follow the manufacturer’s instructions for proper alignment.

Step 5: Attaching the Wheel Hub Puller

Place the wheel hub puller onto the hub assembly, ensuring that the attachment points are securely fastened. The puller should fit snugly and provide a stable grip on the hub assembly.

Step 6: Applying Tension

Using a wrench or socket, tighten the central bolt or nuts of the wheel hub puller. This action will create tension and leverage against the hub assembly. This should gradually separate it from the axle or wheel hub. The manufacturer’s instructions should contain details of the recommended torque or tension specifications for the specific puller being used.

Step 7: Gradually Increase Pressure

Once you have securely attached the wheel hub puller and tension has been applied, you should then gradually increase force by turning the central bolt or nuts further. It’s essential to apply force steadily and evenly to prevent sudden or excessive pressure inadvertently damaging the hub assembly.

Step 8: Check for Movement

As you begin to apply force to the wheel hub puller you should inspect the hub assembly for any signs of movement or separation. You should avoid the temptation to use excessive force as this can compromise safety.

Step 9: Remove the Hub Assembly

Continue applying force until the hub assembly breaks free from its position. Once it has been separated you should carefully remove the hub assembly from the vehicle. While doing this it’s important to ensure that you do not inadvertently damage any surrounding components.

Step 10: Inspect and Replace Components

Once the hub assembly has been removed, inspect the components for any signs of damage, wear, or corrosion. With the hub assembly removed this is a good time to replace worn-out wheel bearings, brake components, or any other parts that might require attention.

Step 11: Reassembling the Wheel Hub Assembly

If you have replaced any components, follow the manufacturer’s instructions for proper reassembly of the wheel hub assembly. Ensure that all components are correctly aligned and tightened to the recommended torque specifications.

Step 12: Install the Wheel

Once the wheel hub assembly is reassembled, place the wheel back onto the vehicle’s wheel studs. Hand-tighten the lug nuts initially, and then use a torque wrench to tighten them to the specifications recommended by the manufacturer.

Step 13: Lowering the Vehicle

Carefully lower the vehicle from the jack stands using a jack, ensuring that it is on a level surface. Once lowered, use a torque wrench to recheck the lug nut tightness to confirm they are properly secured.

Mechanics should also be mindful of any specific safety instructions provided by the manufacturer of the wheel hub puller. This may include guidelines on torque specifications, recommended force application, and any additional safety precautions. Adhering to these instructions ensures the proper and safe use of the wheel hub puller.

Regular inspection and maintenance of the wheel hub puller is also critical for safe usage. The puller should be in good working condition, free from any defects or damages that may compromise its functionality or safety. Any signs of wear or damage should be addressed promptly, and the tool should be properly maintained before it’s used. Damaged wheel hub pullers can represent a safety risk as well as posing a damage risk to the components.

What do you need to consider when using a wheel hub puller?

A wheel hub puller is a valuable piece of equipment that can save time and enhance safety. When using a wheel hub puller it’s important to consider safety. This means ensuring that the vehicle is parked safely and is secure. It also means making sure that you use the correct size and type of wheel hub puller for the specific vehicle and hub assembly. This ensures a correct fit and secure grip.

It’s also important to use the wheel hub puller in line with the manufacturer’s instructions, with force being applied gradually. Excessive or sudden movements should be avoided. The condition of the wheel hub puller should be assessed prior to it being used and the appropriate safety equipment should be used.

By keeping these considerations in mind, mechanics can safely and effectively use a wheel hub puller.

A Comprehensive Wheel Hub Service from CV Hubs & Bearings

CV Hubs & Bearings are specialists in all things wheel hubs. We make it easy to find high-quality wheel hub parts when you need them, and we also provide a comprehensive range of wheel hub services.

If you want to know about the safe use of wheel hub pullers or any other aspect of wheel hub maintenance, replacement, or repair, then our experienced team can help.

If you have any questions or would like to know more about our services, call +44 (0) 161 370 3344 or contact us online.

Back to news